Emerald Energy's

Corrosion Services

Emerald Energy’s corrosion services provides our clients with industry leading corrosion and cathodic protection inspection. Corrosion is the leading cause of piping and storage tank failures worldwide. Our ability to effectively inspect this infrastructure allows us to illustrate both viability and potential hazards to their piping and storage systems.

Emerald Energy utilizes cutting edge corrosion control equipment designed to provide a superior product. As with everything else we do, Emerald Energy strives to be the ultimate standard in corrosion control and cathodic protection. That is just the Emerald Way.

Industry Leading Corrosion and Cathodic Protection Inspection

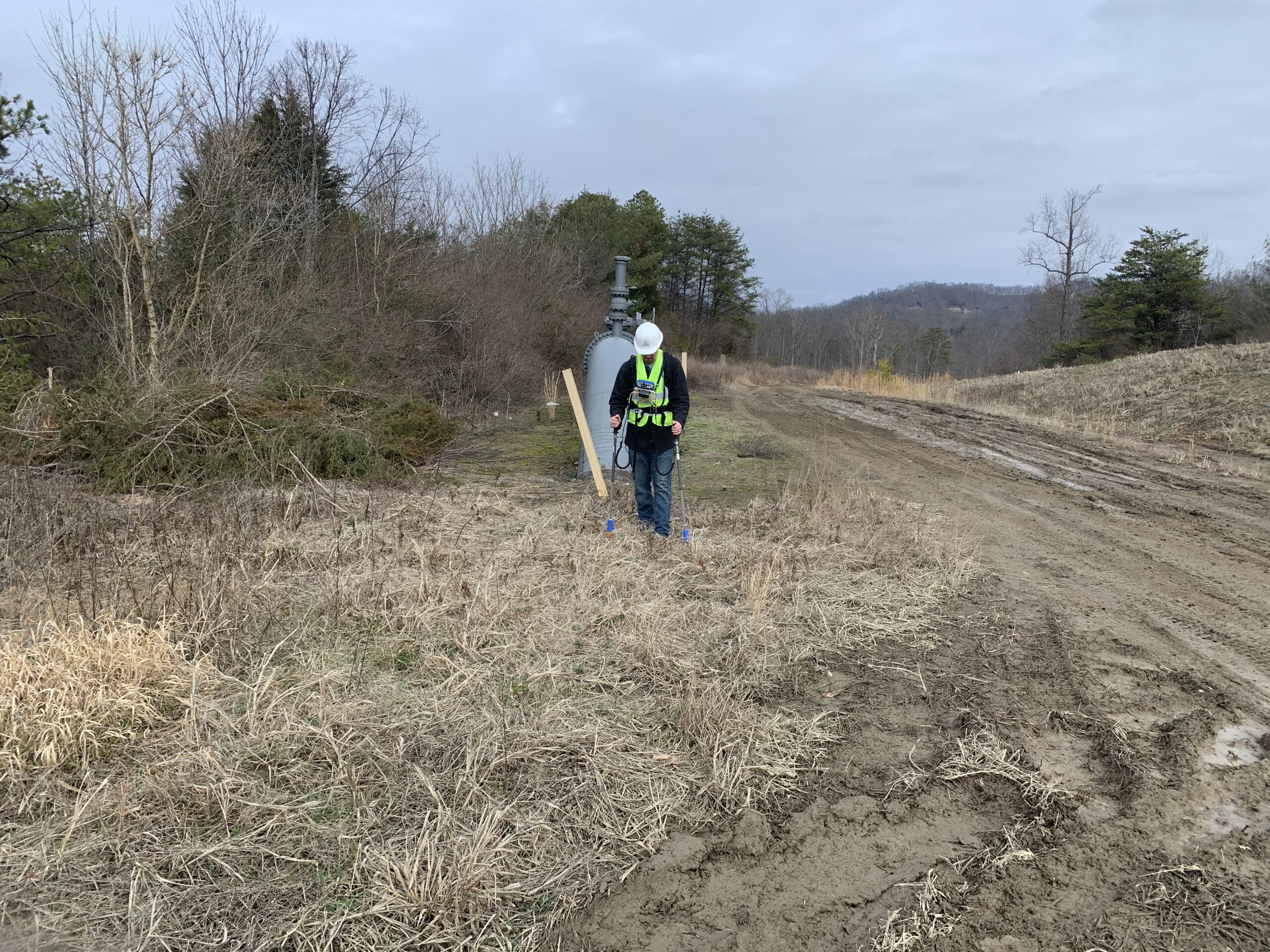

Close Interval Surveys

We offer industry leading surveys using the latest technology in the industry. Surveys can be customized to meet the client's needs. We are here to make your job easier. Give us a call and let us change how you do surveys.

Coating Surveys

-Direct Current Voltage Gradient (DCVG)

-Alternating Current Voltage Gradient (ACVG)

-Net Protective Current (Side Drain Survey)

Internal Monitoring

-Coupon Data Analysis

-Gas Sampling/Quality Analysis

-Liquid Sampling/Quality Analysis

Reporting

All reports include graphs, mapping, and GPS, and are fully customizable to meet a client’s needs.

Coating Inspection

-Atmospheric Corrosion

Field Applied Coating and Coating Repairs

A Fully Trained and Certified Staff Ready to Hit the Ground Running

Emerald Energy’s corrosion team is NACE certified